Marchwood Power Station operates a combined-cycle gas turbine (CCGT) process to produce electricity.

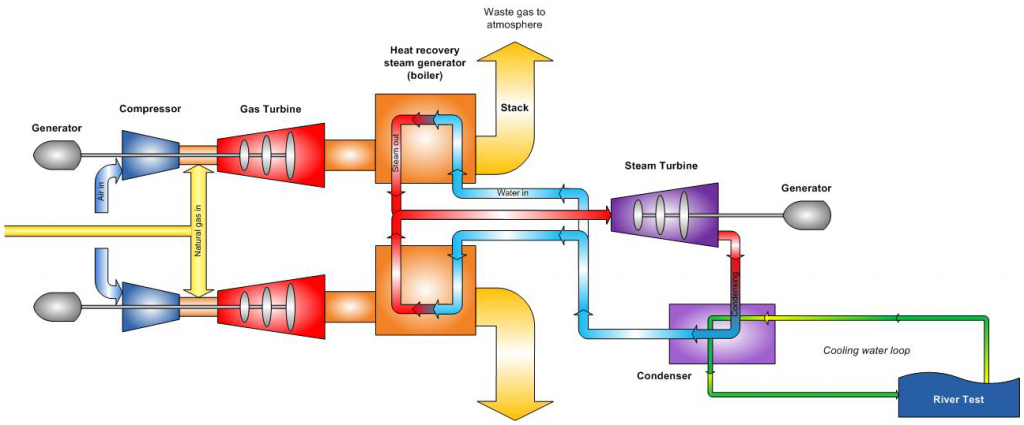

Natural gas is transported to site via a 22km pipeline. At the power station, air goes through a compressor and is mixed with natural gas in the combustion chamber and burned. The hot combustion gasses expand, driving the gas turbines and turning the generators to produce electricity.

The Power Station has two gas turbines and one steam turbine.

The hot exhaust gases from the gas turbines contain a lot of energy and these gases are passed through the heat recovery steam generator to produce steam. The high pressure steam is used to drive a steam turbine which generates further electricity.

The waste gases are expelled to the atmosphere via the stack.

Once the steam has driven the turbine it passes through a condenser to convert the steam to water and this is recycled through the heat recovery steam generator. The condenser requires large quantities of cooling water from the River Test which is discharged back to the river fractionally warmer.

The water intake and outfall structures are those used from the previous power station and have been refurbished.

The quality and temperature of the water discharged back to the river is carefully controlled as part of the Environmental Permit.

The CCGT Process

The term ‘combined cycle gas turbine’ (CCGT) is used because the process uses hot gasses firstly to drive a gas turbine and then uses the same gasses from the gas turbine exhaust to produce steam to drive the steam turbine.

The CCGT process is efficient and the overall efficiency of the power station is more than 59.5% and produces more than 895MW’s (this would power about 340,000 kettles).